Pulling away on plastic

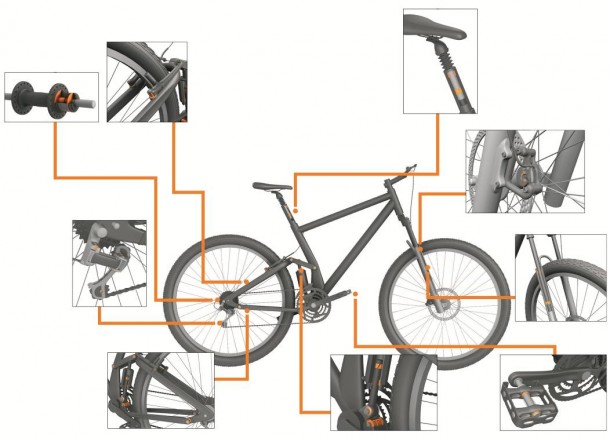

Versatile applications in the bicycle industry use igus plain bearings

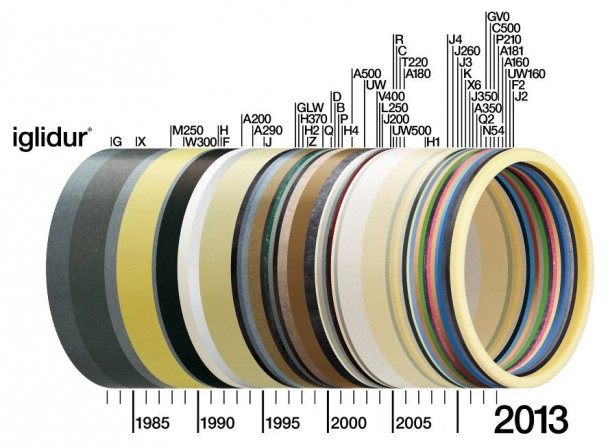

Over the past three decades, "iglidur" polymer plain bearings from igus have been increasing the service life of numerous applications and playing out their technical and economic advantages in many areas, including bicycle engineering. Maintenance-free dry running, weight reduction, corrosion freedom and sturdiness are advantages of all polymer plain bearings from igus.

There are more bicycles than cars in the world. They are used for day-to-day transport, to keep fit, as company vehicles and leisure status symbols. Even more varied than the application purposes are the variants and categories available these days, from Dutch bikes to Pedelecs. One thing they all have in common, however is the heavier the bikes are, the more power and effort the rider needs to move forwards. At the same time, bearings have to work smoothly and reliably long-term even under rough conditions such as soiling and impact loads. Plastic plain bearings from igus help in both cases: they save weight and work reliably without lubrication even under the most adverse conditions. igus’ years of experience in this segment are illustrated by the fact that wear-resistant iglidur bearings in the rear derailleurs, contributed to three medals in the mountain-bike competitions at the Olympic Games in Athens in 2004. iglidur bearings – in the suspension fork this time – were also involved in the gold medal won by Sabine Spitz at the 2008 Olympics.

The fields of application for iglidur plain bearings in bikes are extremely varied. They replace metallic ball bearings in the freewheel of hubs and pedals and help reduce costs. They guarantee safety in the brake lever and brake kinematics. In rear and front derailleurs they contribute to power transmission with maximum smoothness. They increase riding comfort and safety in front and rear springs as well as in spring-loaded seat posts. And, all without lubrication and maintenance effort.

Research and development in the test laboratory

igus is an expert in the field of tribologically optimised plastics (tribology: Greek for the science of friction). Year after year, numerous new materials are developed on the basis of compounded material and put through their paces. The home-grown iglidur high-performance plastics from igus are subjected to continuous testing with regard to durability, friction and wear in the test laboratory in Cologne, which has an area of 1,750 m². The wide range of plain bearing tests – no less than 14,000 in the year 2012 alone – has resulted in the establishment of a unique company database recording the tribological properties of the polymers. Under rough industrial conditions, interactive surfaces in relative movement are investigated and tested completely in keeping with the definition of “tribology” so that correspond to the respective requirements in a wide range of different applications. The basis of each iglidur polymer bearing is the thermoplastic matrix material with its already outstanding properties, which is carefully selected to match the requirements profile. This usually has reinforcement fibres embedded to increase pressure resistance, as well as solid lubricants which optimise wear resistance and friction. These solid lubricants are of significant importance for the dry running performance of the iglidur plain bearings since – integrated in the matrix – they always work at the contact surface between shaft and bearing. The plain bearings release tiny quantities of the solid lubricant – stored as microscopically small particles in the matrix material – which suffices to lubricate the immediate environment. Compared to ball bearings, plain bearings provide a better distribution of load over the larger area – an advantage in short-frequency pivoting movements of the spring kinematics from “Fullys” for example.

The advantages weigh heavy

No matter where the plastic plain bearings are used, weight reduction is always a major advantage. The plastic bushings only weigh about one third of what comparable metallic alternatives weigh. At the same time, they are sturdy enough to cope with soiling and dirt as well as edge loads and impact reliably and in the long term. They are also corrosion-free and have low and constant friction values – even on low-price soft shafts or bolts. High wear-resistance even at high-frequency short stroke movements is a further benefit. Numerous renowned bike and component manufacturers – not only in the mountain-bike sector – thus rely on plastic bearings from igus. They can choose from the large catalogue range of polymer bearings or work with igus on designing tailor-made, application-specific solutions.

Author: Dipl.-Wirt. Ing. René Achnitz, head of the iglidur plain bearings division at igus GmbH

|

PRESS CONTACT:

Oliver Cyrus Head of Press and Advertising

igus® GmbH Spicher Str. 1a D-51147 Cologne Tel. +49 22 03 / 96 49-459 Fax +49 22 03 / 96 49-631 ocyrus@igus.de |

ABOUT IGUS:

igus GmbH is a world's leading manufacturer in the field of energy chain systems and polymer plain bearings. The family-run company is based in Cologne, represented in 33 countries and contracts 2,200 employees worldwide. In 2012 igus generated a turnover of 399 million Euro. igus operates the largest test laboratories and factories in its industry to offer customers innovative and tailor-made products and solutions within the shortest time. |

The terms “igus, e-ketten, e-kettensysteme, chainflex, readycable, easychain, e-chain, e-chainsystems, energy chain, energy chain system, flizz, readychain, robolink, CFRIP, pikchain, triflex, twisterchain, invis, drylin, iglidur, igubal, xiros, xirodur, plastics for longer life, manus, vector” are legally protected trademarks in the Federal Republic of Germany and, where applicable, in some foreign countries.

Captions:

Photo 1

Plastic plain bearings from igus are fitted in numerous different places on bikes. (Source: igus GmbH)

Photo 2

In the course of 30 years, more and more iglidur materials were produced, each with new, application-related properties. (Source: igus GmbH)

Photo 3

14,000 plain bearing tests were carried out in the largest test laboratory in the branch (1,750 m²) in 2012 alone. (Source: igus GmbH)

Photo 4

iglidur plain bearings from igus are used in seat posts, too. (Source: igus GmbH)

Photo 5

The plastic plain bearings from igus provide a larger contact area than roller bearings. Result: Better distribution of load coupled with high torsion resistance. (Source: igus GmbH)